| Step |

What |

Why |

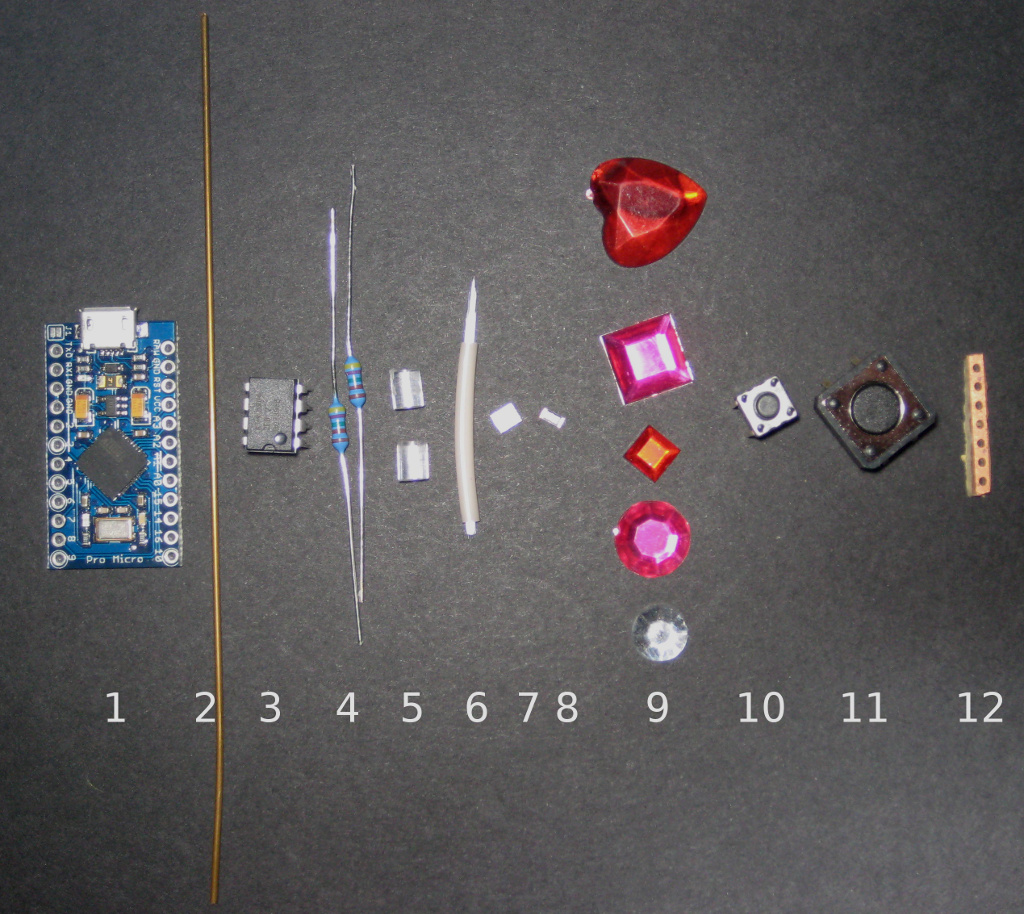

| Brass rod/wire, 1mm thick |

Brass rod (1mm) is easy to

bend and strong enogh to make a proper handle. Thinner brass

rod is too soft. Thicker brass rod is very hard to bend.

Aluminium is too soft. Anything with plain iron will

rust. High quality steel is too hard. Silver is too soft. Go

for gold alloy, used for tooth crown, if you have the money.

Its even shinier than brass ;-) |

|

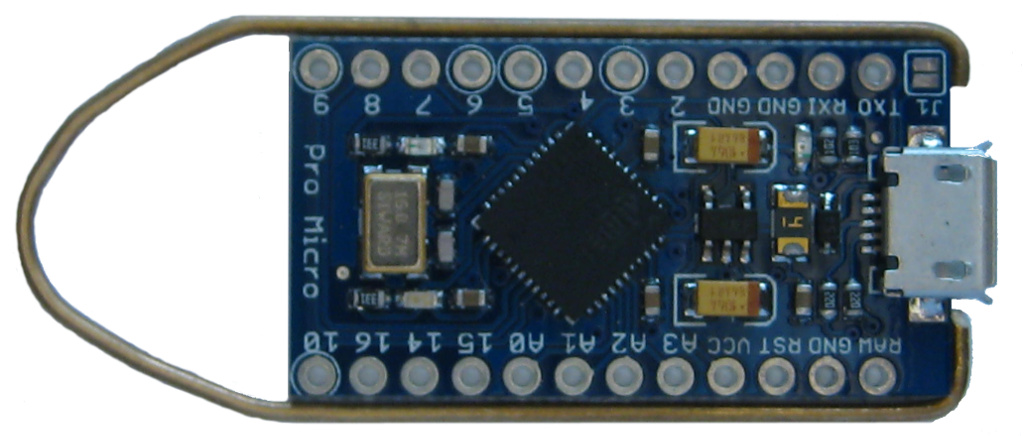

| 2.0 |

dremel or sand the edges of

arduino pro to get "round" soft edges at the usb side of the

board |

It is close to impossible to

bend the rod to a 90° angle. Its always a bit round at

the edge. As you will want a close fit you have to get rid

of the sharp edges at the usb port side of the circuit

board. This is not a problem on the other side (not usb ...). There is no 90 degree angle for the brass rod. |

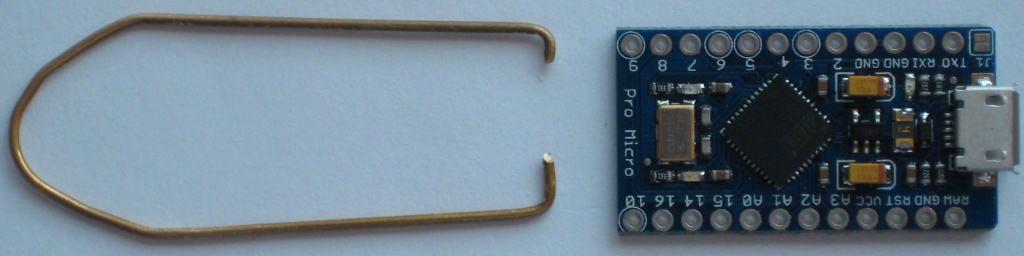

| 2.1 |

cut about 12 cm from a brass

rod of 1mm diameter |

Do this first because its

handy to have an extra part to handle the arduino in all

steps following. Dont use anthing thinner, because its too

fragile then. Dont use anything thicker as 1 mm as it will

be very hard to bend. |

| 2.2 |

bend 3-5 mm as tight and

close to 90 degrees for the usb side as possible |

If you sanded the edges

properly, the rod will have a tight fit which is essitial

for handling the board afterwards. These bended parts of the

rod take the load for any drag on the opposite side. If you

dont have tthem the glue at the sides of the board has to

take the load alone. This is not prefereable. |

| 2.3 |

bend it to a curve on the

other side with a distance of 1-2 cm from the board |

If you need a large curved

rod to even put your finger through it, make it larger. I

only want it to hang an a hook or to attach it to a key

ring. |

| 2.4 |

bend it as tight and close to

90 degrees as possible for the other edge close to usb. Cut off the part which does not fit :).  |

see 2.2 Its no problem if the rod just slightly touches the usb port as it is grounded. But the rod should not move away from the board because the bent part is too long. Remember : a tight fit is the goal. Bend it a little more than necessary, like in the image to the left. It will clamp itself to the board and is easy to glue. If its too loose you will have a lot of trouble glueing it. |

| 2.5 |

make sure to have a flat

construction that fits exactly around the circuit board |

If your construction is not

flat you will not be able to glue it around the circuit

board. Instead you will be ruining your fingers, the circuit

board, your clothes and anything close to your handling area

in the attempt to get it done. If you get a fit like the one shown in image 2.5 you can lift the board and the rod will still cling to arduino. Now its ready to get glued. |

| 2.6 |

Glue it around the board with

heavy duty two component glue and let it cure. Make sure

that it does not touch any contacts/conducting parts. Dont use too much gluu. You might spoil contacts on your arduino board. If you have a glue which is more fluid than solid then solder stuff first and glue afterwards. If you have some gelatinous glue its perfect. |

I always use a strong 24 hour

curing 2 component glue to make sure that i get a strong and

durable connection. Dont use super glue or any stuff which

goes hard like a crystal after curing. Its not very usefull

for parts with large gaps. And dont use anything soft like

regular paper glue. It will not even hold the circuit board

alone if bad luck hits you. Hot glue might be an alternative

if you have a gluegun with a very fine tip. Otherwise you

will find glue all over the place. And its not as strong as

i want the bonding to be. |

| Step |

What |

Why |

| 4.0 |

Cut off one line from a

stripboard, seven holes long. |

This line will fit onto the

arduino micro pro board. Any stripboard with 2.54 mm distance between holes will do it. Otherwise you have to recalculate length. Anyway, only one hole has to fit exactly : GND. The other end will be connected by a wire, so there does not have to be an exact match of holes at the ends of our mini-led-board with the arduino board. |

| 4.1 |

Cut the copper line at 2

holes, one exactly in the middle, thats where the led goes. |

The two cuts are the mounting

places for a resistor and the led. The resistor has to have

a minimum of 160 Ohm. A red LED needs about 1.8 Volt at 20 mA. As we are running our finalkey from usb port, 5 Volt will kill it without a resistor taking the voltage up to 5 Volt. R=U/I -> R= 3.2Volt / 0.02 mA -> R=160. Depending on your LED and its brighness you can go up to several hundred Ohm and it will still be bright. Nowadays LEDs might blind you if you run them with maximum allowed current. |

| 4.2 |

Solder resistor and led over

cuts, test it at 5 Volts ! Resolder if necessary. |

I used a 180 Ohm resistor

which protects the red led and still allows enough current

to make it shine bright. Dont connect it to arduino yet. NO GLUE, NO SOLDERING to arduino. You have to glue fiber optics to red power led first. This is located to some extent below the finalkey led stripboard. See image 4.4. Attention reset button users : If you want a reset button you better solder the resistor to the right and cut off 2 holes from the stripboard on the left. You will need this space for the reset button |

| 4.3 |

Solder connections for GND

and arduino output . DONT connect it to arduino yet! |

The connected wire make a

good handle, the ground pin makes it easy to adjust the

board for the following 2 steps. |

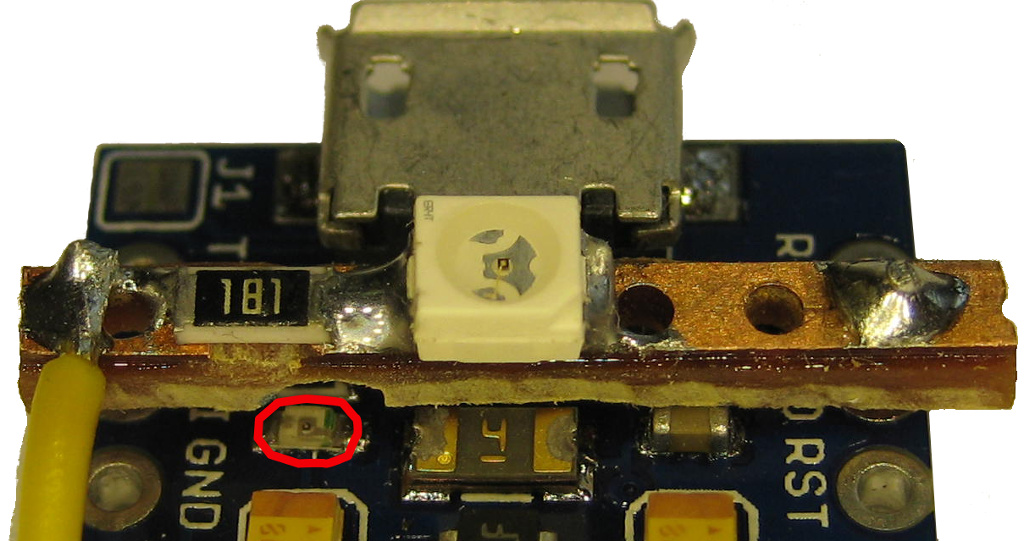

| 4.4 |

Mark position of red power

led on your stripboard |

Dilemma dilemma! The red power led is partly covered by the finalkey stripboard mount. Solution : mark the position of the power led and remove some stripboard. You might turn the board and connect ground to the other side of the arduino board. There are two GND connectors. But this option will give you more pain to run fiber-optics below the finalkey stripboard. |

| 4.5 |

Cut a path for fiber-optics

at the mark you just made into your stripboard. You should

have a clear view to the red power led on the arduino board

now (inside red oval) |

As you will glue your fibers

at an angle of about 45 degrees you need some space below

the stripboard. Once you can see the power led like

this (see image 4.5) you are done with the stripboard

preparation. If you have a shortened stripboard to have some space for the reset button you will not need this extra grinding |

Arduino pro micro with fiber optics (left, ontop the red power LED

and glued light pipes (right to eeprom, clear)

| 5.1 |

Glue one end of your

fibers about 2-3 mm so that you can cut them to an

angle of about 45 degrees afterwards. Let it cure |

As the fibers are to be bend around the eeprom it is not a good idea to mount them vertically. They are flexible but if you try too hard they will brake. |

| 5.2 |

Cut the glued fibers at an

angle of about 45 degrees on led (see image above). Glue it to red power led (see image above) Dont use too much glue otherwise your finalkey-stripboard will not fit and you have to do more grinding. |

To get a good transition of

light from led to fibers -> 45° +/- 10°

will do it. Use a fast curing glue (minutes) otherwise your hand will get tired. A 3d hand or any mechanical solution will most probably not do it. |

| 5.3 |

Cover the glue with black

paint or any non transparent color or glue. |

If you dont cover it there is

enough light left outside the fibres to irritate the

finalkey gem above . |

See image below at Nr.7.

Button is connected to pin 7 and 9 (two white cables, bottom

right)

The following image has more stuff glued already : fiber optics

have been marked red.

The upper part on the right will be cut later to match

surface.

The finalkey led is covered already with glue (the more or less

white stuff the arrow is pointing to)

Glue it over fibre-optics.

Connect it to GND and arduino pin10.

( the yellow cable seen in the image above is connected to reset!

The finalkey-led cable is running to the other side in front of

the pushbutton to pin 10 . Its covered with glue in this

image already.)

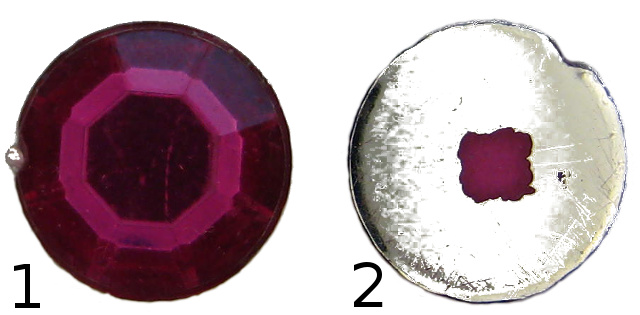

If you get cheap gemstones from a dollar/euro-shop they will most likely have a reflecting backside. If they do, you have to remove some part of it to let your led shine through. Otherwise you will not see your led blink.

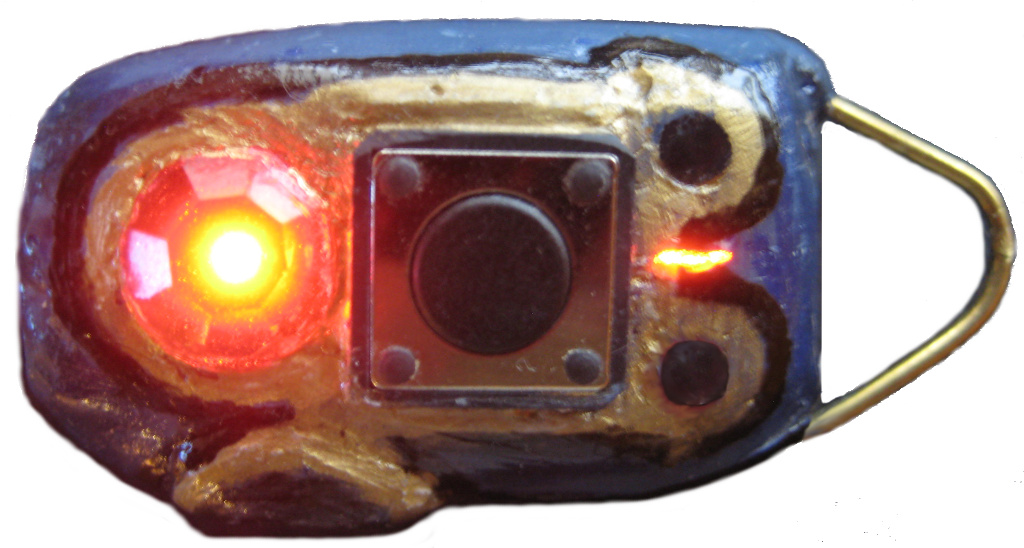

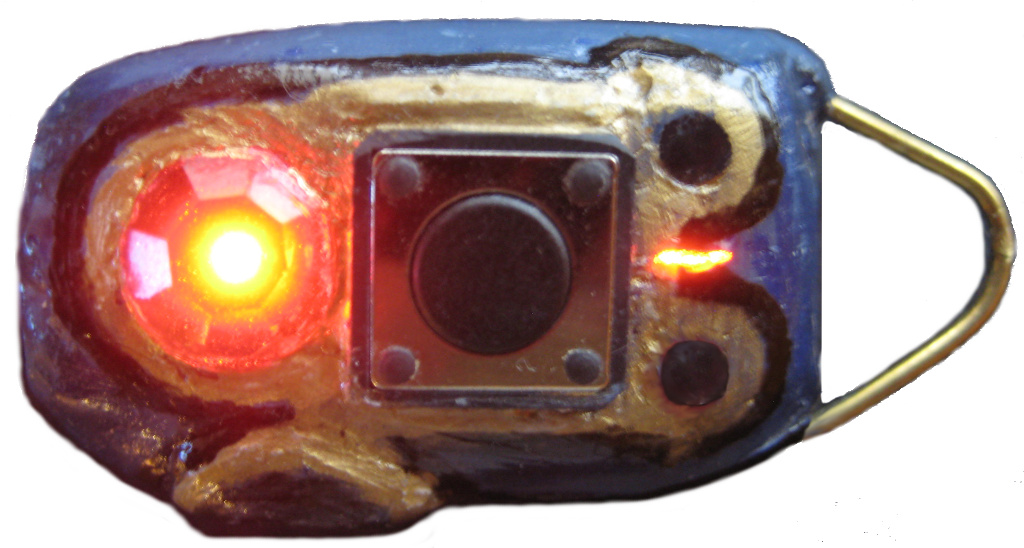

1 : gemstone front, not prepared

2 : gemstone backside with part of the reflector removed. This is

where your finalkey-led will sit.

Dont remove all reflective layer. If

you do your gemstone will be less shiny.

Try to put your gemstone exactly above

the removed part of the reflector.

The reset button is not necessary for regular use. Only if you

want to write your own code or you want to debug your code its

useful. And as dusted emphasized : its a security risk. You can

only program arduino by usb once its covered. Anybody will be able

to read your eeprom by using the rest button to get into

programming mode. Its crypted, ok, but its a risk anyway. I have

used finalkey several month now and it never got stuck or needed a

reset.

Enjoy

|

Design and hardware extensions used for Red Heart, Alien Artefact and Green Miracle : tc (thunderchild), Nov 2014 |

All praise and credit for FinalKey hardware and software go to dusted.